- Home

- Products

- Elementary

- Boride Powder

- 3D Printing Powder

- Sulfide Powder

- Oxide Powder

- Carbide powder

- Nitride Powder

- Silicide Powder

- Hydride Powder

- Telluride Powder

- Selenide Powder

- Stearic Acid Series

- Phosphide Powder

- Nanoparticles

- Metal Alloy

- MAX Phase

- Lithium Battery Anode

- Surfactant

- Molecular sieves

- Concrete Admixtures

- Cladding of metals

- News

- Blog

- Contact

- About

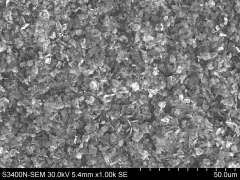

The Difference Between Natural Graphite and Artificial Graphite

The difference between natural graphite and artificial graphite:

Source and preparation

Natural graphitemainly comes from graphite ore obtained by mining, crushing, grinding, and other processes. The preparation process is relatively simple, and the cost is low. Various methods, such as high-temperature carbonization, chemical vapor deposition, graphitization, etc, can prepare artificial graphite. The preparation process of artificial graphite is relatively complex, and the cost is high.

Structure and property

Natural graphite has a layered structure in which carbon atoms are connected in planes by covalent bonds, and the layers interact with each other by weaker van der Waals forces. This structure makes natural graphite have good electrical conductivity, thermal conductivity, and lubricity. The structure of artificial graphite can be adjusted according to the preparation method and conditions to obtain graphite materials with different properties. For example, artificial graphite can obtain graphite powder by controlling carbonization temperature and time or improving its conductivity, thermal stability, and other properties by adding other elements or compounds.

Application field

Natural graphite and artificial graphite are also different in the field of application. Natural graphite is mainly used to make electrodes, lubricants, sealing materials, etc. For example, in the battery industry, natural graphite as a negative electrode material has a high capacity and good cycle performance. Artificial graphite is widely used in electronics, aerospace, chemical, composite materials, and other fields. For example, In the aerospace field, artificial graphite is used to manufacture high-temperature sealing materials and thermal protection systems.

The advantages of natural graphite and artificial graphite

Advantages of natural graphite

(1) Rich resources: Natural graphite is widely distributed in the crust, has rich reserves, and is easy to exploit and process. This makes natural graphite have a great advantage in price and become the main choice in many fields.

(2) Good electrical and thermal conductivity: the layered structure of natural graphite makes it have good electrical and thermal conductivity, suitable for electronic, electrical, communication and other fields. At the same time, its lubricating properties also make natural graphite an ideal choice for manufacturing lubricants and sealing materials.

(3) Environmentally friendly: The preparation process of natural graphite is relatively simple, without using many chemical reagents and equipment, and has little impact on the environment. In addition, natural graphite is a natural resource, and the waste generated during its mining and processing can be recycled, which has a high environmental protection value.

Advantages of artificial graphite

(1) Adjustable performance: By adjusting the preparation method and conditions, artificial graphite materials with specific properties can be obtained. For example, graphite powder with different particle sizes and specific surface areas can be obtained by controlling carbonization temperature and time By adding other elements or compounds to improve its electrical conductivity, thermal stability, and other properties. This flexibility gives artificial graphite a wide range of applications in many fields.

(2) High strength and wear resistance: artificial graphite has high mechanical strength and wear resistance, suitable for manufacturing wear-resistant materials and seals. For example, artificial graphite is used to manufacture key components such as wear-resistant pumps and valves in the chemical and petroleum fields. In aerospace, artificial graphite is used to manufacture high-temperature sealing materials and thermal protection systems.

Graphite sheet powder market prospects:

Graphite sheet powder has excellent electrical conductivity, thermal conductivity, lubrication, and chemical stability characteristics, making it in electronics, electrical, communications, aerospace, chemical, metallurgy, and lubrication. With the technological progress and industrial upgrading in these fields, the application field of graphite sheet powder will continue to expand.

In electronics, graphite sheet powder is widely used in manufacturing batteries, electronic components, displays, and other products. With the rapid development of emerging industries such as new energy vehicles, wearable devices, and smart homes, the demand for graphite sheet powder in electronics will continue to grow.

In the chemical industry, graphite sheet powder, an important chemical raw material, is used to manufacture various graphite products, such as graphite electrodes, seals, graphite coatings, and so on. With the rapid development and industrial upgrading of the chemical industry, the application of graphite sheet powder in the chemical field will continue to expand.

Supplier of Natural graphite:

Synthetic Chemical Nano Technology Co. Ltd. is a trusted supplier and manufacturer of chemicals and Nanomaterials. They have over 12 years of experience providing high-quality chemicals.

Send us an inquiry if you're looking for high-quality Natural graphite. ( sales5@nanotrun.com )

Inquiry us