- Close

- Home

- Products

- Elementary

- Boride Powder

- 3D Printing Powder

- Sulfide Powder

- Oxide Powder

- Carbide powder

- Nitride Powder

- Silicide Powder

- Hydride Powder

- Telluride Powder

- Selenide Powder

- Stearic Acid Series

- Phosphide Powder

- Nanoparticles

- Metal Alloy

- MAX Phase

- Lithium Battery Anode

- Surfactant

- Molecular sieves

- Concrete Admixtures

- Cladding of metals

- News

- Blog

- Contact

- About

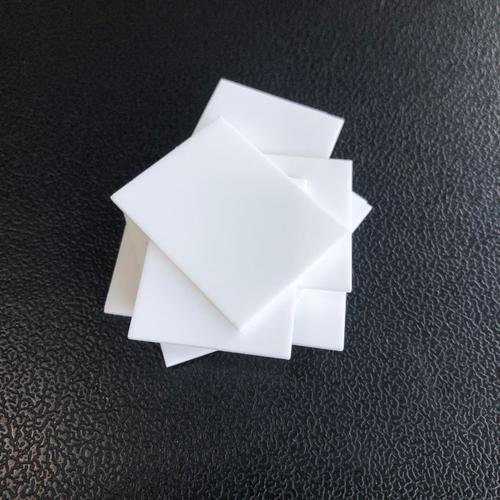

Molybdenum Boat Mo Boat

Molybdenum Boats are mainly used in fields such as aperture cleaning and vacuum deposition. This type of molybdenum boat usually has a specific thickness (such as 0.05mm), length (such as 75 mm total length), and boat groove size (such as 12mm in length, 5mm in width, and 1mm in depth).

The excellent performance of molybdenum boats makes them an ideal choice for vacuum deposition and other high-temperature and high-vacuum applications. It can maintain stability at high temperatures and is not easily reactive with many materials, making it widely used in the preparation of thin films, coatings, and other materials.

The application fields of Molybdenum Boats are quite extensive, mainly reflected in the following aspects

Coating technology: Molybdenum boats are often used as key equipment in coating technology. Due to their excellent high-temperature and chemical stability, molybdenum boats can work stably for a long time in high-temperature and high-vacuum environments, making the coating preparation process more reliable and efficient.

Electronics industry: In the electronics industry, molybdenum boats are an important tool for preparing electronic materials. For example, in the preparation process of semiconductor materials, molybdenum boats can serve as evaporation sources to evaporate and deposit materials on substrates, thereby producing thin films or other structures.

Power engineering: Molybdenum boats also play an important role in power engineering. It can be used as a material holding device for capacitor sintering, vacuum thermal evaporation, and nuclear fuel sintering, ensuring more accurate and reliable material handling in the manufacturing and maintenance process of power equipment.

Vacuum evaporation: The molybdenum boat is a key component in vacuum evaporation technology. It heats the material to evaporation and then deposits it on the substrate in a vacuum environment to form the required thin film or coating.

Other fields: Molybdenum boats may also be applied in other fields, such as scientific research, material preparation, and processing, especially in experiments and process processes that require high-temperature and high-vacuum environments.

Packaging & Shipping of Molybdenum Boat Mo Boat:

We have several sort of packaging which depend upon Molybdenum Boat Mo Watercraft amount.

Molybdenum Boat Mo Watercraft delivery: might be shipped out by sea, by air, by reveal immediately once repayment receipt.

Supplier Synthetic Chemical Nano Technology Co. Ltd. is a trusted supplier and manufacturer of chemicals and Nanomaterials. They have over 12 years of experience providing high-quality chemicals.

Send us an inquiry if you're looking for high-quality Molybdenum Boats,please feel free to contact us. ( sales5@nanotrun.com )

FAQ:

Q1:

What are the materials and characteristics of molybdenum boats?

Answer:Molybdenum boat is mainly made of molybdenum, which is a metal with a high melting point, high thermal conductivity, and good chemical stability. This enables the molybdenum boat to withstand high temperature, high pressure, and chemical corrosion, thus maintaining stable working conditions in many extreme environments.

Q2:

What is the purpose of a molybdenum boat?

Answer:Molybdenum boats are mainly used for material heating, melting, or evaporation experiments in high-temperature furnaces. They are commonly used in fields such as vacuum deposition, electron beam evaporation, and physical vapor deposition and are important tools for preparing materials such as thin films, coatings, and electronic components.

Q3:

How to choose and use molybdenum boats?

Answer:When choosing a molybdenum boat, factors such as size, shape, purity, and the maximum temperature it can withstand need to be considered. When using a molybdenum boat, it is necessary to follow relevant operating procedures to ensure that it operates at the correct temperature and vacuum environment and to avoid excessive heating or damage.

Q4:

What are the precautions for cleaning and maintaining molybdenum boats?

Answer:When cleaning the molybdenum boat, appropriate cleaning agents and tools should be used to avoid using substances that may cause damage to it. At the same time, attention should be paid to protecting the surface of the molybdenum boat to avoid scratches or contamination. Regular inspection and replacement of aged molybdenum boats are also important measures to maintain their good working condition.

Q5:

What are the safety operating regulations for molybdenum boats?

Answer:When using a molybdenum boat, it is necessary to comply with relevant safety operating procedures, such as wearing personal protective equipment such as protective glasses and gloves, ensuring good ventilation in the work area, and keeping away from flammable and explosive materials. At the same time, it is important to observe the working status of the molybdenum boat during operation and promptly detect and handle any abnormal situations.

Inquiry us

PREVIOUS Elementary

High Purity Selenium Se Powder CAS 7782-49-2, 99%

NEXT Elementary