- Home

- Products

- Elementary

- Boride Powder

- 3D Printing Powder

- Sulfide Powder

- Oxide Powder

- Carbide powder

- Nitride Powder

- Silicide Powder

- Hydride Powder

- Telluride Powder

- Selenide Powder

- Stearic Acid Series

- Phosphide Powder

- Nanoparticles

- Metal Alloy

- MAX Phase

- Lithium Battery Anode

- Surfactant

- Molecular sieves

- Concrete Admixtures

- Cladding of metals

- News

- Blog

- Contact

- About

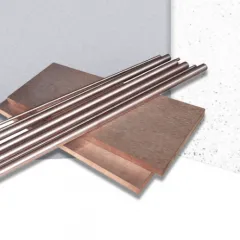

Metal Alloy W-Cu Alloys Bar Custom Size Tungsten Copper Alloy Rod

Description of Metal Alloy W-Cu Alloys Bar Custom Size Tungsten Copper Alloy Rod:

High density

Tungsten copper rod has a high density. Its density is usually higher than pure tungsten rod, so in the same volume, tungsten copper rod is heavier than pure tungsten rod. This high density makes the tungsten copper rod stable under the action of gravity and not easy to deform or bend.

High strength and hardness

Tungsten copper rod has high strength and hardness, higher strength and hardness than pure tungsten rod. These high strength and hardness characteristics enable tungsten copper rods to withstand greater loads and impact forces and have better mechanical properties.

Excellent electrical conductivity

A tungsten copper rod has good electrical conductivity, and its electrical conductivity is better than a pure tungsten rod. This conductivity enables tungsten copper rods to transmit more current when energized.

Excellent corrosion resistance

Tungsten copper rod has good corrosion resistance, more corrosion resistance than pure tungsten rod. This corrosion resistance enables tungsten copper rods to maintain stable chemical properties in various corrosive environments and is suitable for the manufacture of various corrosion-resistant parts and structural parts.

Good processing performance

Tungsten copper rod has good processing performance and can be carried out in a variety of machining operations, such as turning, milling, drilling, cutting, and so on. This good processing property makes tungsten copper rod has a wide range of application value in the field of mechanical manufacturing.

Good fatigue resistance

Tungsten copper rod has good fatigue resistance, more fatigue resistance than pure tungsten rod. This fatigue resistance enables tungsten copper rods to maintain stable performance when subjected to periodically changing loads. It is suitable for manufacturing a variety of components and structural parts that need to resist fatigue.

Good antioxidant properties

Tungsten copper rod has good oxidation resistance, more oxidation resistance than pure tungsten rod. This oxidation resistance enables tungsten copper rods to maintain stable chemical properties in high-temperature environments and is suitable for manufacturing various high-temperature components and structural parts.

Technica information of Tungsten Copper Rod :

| Article | 90W/ 10Cu | 85W/ 15Cu | 80W/ 20Cu | 75W/ 25Cu | 70W/ 30Cu | 60W/ 40Cu | 50W/ 50Cu |

| Density | 16.75 | 15.9 | 15.15 | 14.5 | 13.85 | 13.15 | 11.85 |

| Product | Surface | Thickness | Width | Length | |

| T | Tolerance | ||||

| W-Cu Alloy sheet | Grind | >=1.5-70 | +-0.05 | <=200 | <=500 |

Application of Metal Alloy W-Cu Alloys Bar Custom Size Tungsten Copper Alloy Rod:

Electronic industry field

Tungsten copper rods can be used to manufacture various electronic equipment parts and structural parts, such as integrated circuit shells,

transistor electrodes, and so on. In addition, tungsten copper rods can also be used to manufacture a variety of wire and cable conductor cores.

The field of machinery manufacturing

Tungsten copper rod has a wide range of applications in the field of mechanical manufacturing. Because of its high strength, high hardness,

excellent processing performance, and fatigue resistance, it can be used to manufacture various parts and structural parts, such as guide rails,

spindles, pistons, and other parts of machine tools. In addition, tungsten copper rods can also be used to manufacture various gears, bearings,

and other transmission components.

Aerospace

Tungsten copper rod is widely used in the aerospace field. Because of its high strength, high hardness, and oxidation resistance, it can be used

to manufacture components and structural parts of aircraft engines, such as turbine blades and compressor blades. In addition, tungsten copper

rods can also be used to manufacture spacecraft main engines and boosters.

Energy

Tungsten copper rod is widely used in the energy field. Because of its high density and high strength, it can be used to manufacture electrode

materials for various batteries, such as positive electrode materials for alkaline batteries and negative electrode materials for nickel-metal hydride

batteries. In addition, tungsten copper rods can also be used to manufacture electrode materials for various fuel cells.

Sports

Tungsten copper rod is widely used in the sports field. Because of its high strength high hardness, it can be used in the manufacture of golf clubs,

bows and arrows, and other sports equipment. In addition, tungsten copper rods can also be used to manufacture parts such as the barrel of

various shooting equipment.

Construction field

Tungsten copper rod is widely used in the construction field. Because of its high strength high hardness, it can be used to manufacture glass

curtain wall brackets, high-rise building railings, and other components. In addition, tungsten copper rods can also be used to manufacture a

variety of decorative doors and Windows.

Nuclear industry

Tungsten copper rod is widely used in the nuclear industry. Because of its high strength, high hardness, and oxidation resistance, it can be used

to manufacture the control rod drive mechanism of nuclear reactors, the cladding of nuclear fuel elements, and other components. In addition,

tungsten copper rods can also be used to manufacture structural parts of nuclear waste disposal devices.

Production Method of Metal Alloy W-Cu Alloys Bar Custom Size Tungsten Copper Alloy Rod:

Powder metallurgy process

Powder metallurgy is a method to prepare tungsten-copper alloy materials by mixing tungsten and copper, two metal powders together, and then sintering and densification. The method has the advantages of low production cost and high material utilization. It is suitable for the production of tungsten copper alloy products with complex shapes and high precision requirements. The basic process of powder metallurgy includes powder preparation, mixing, pressing, sintering, and densification. In the production process, it is necessary to control the particle size, composition, pressing pressure, and sintering temperature of the powder to ensure the density, strength, and electrical conductivity of the product.

The electric spark melting method

The electrospark melting method is a method to prepare tungsten-copper alloy material by melting tungsten and copper together using an electric spark. The method has the advantages of high melting temperature, uniform alloy composition, etc. It is suitable for producing tungsten copper alloys with high melting point, high purity, and high performance. The basic flow of the EDM process includes electrode preparation, melting, pouring, and cooling steps. In the production process, it is necessary to control factors such as melting temperature, electrode composition, and cooling speed to ensure the melting quality and performance of the product.

Vacuum melting method

Vacuum smelting is a method to prepare tungsten copper alloy materials by melting tungsten and copper together in a vacuum state. The method has the advantages of a clean melting environment, uniform alloy composition, etc., and is suitable for producing high-purity and high-performance tungsten-copper alloy materials. The basic process of vacuum smelting includes the steps of batching, furnace loading, vacuum pumping, heating, melting, pouring, and cooling. In the production process, it is necessary to control the ingredients, melting temperature, cooling speed, and other factors to ensure the melting quality and performance of the product.

Payment and Transportation:

Metal Alloy W-Cu Alloys Bar Custom Size Tungsten Copper Alloy Rod Properties | |

| Other Titles | Tungsten Copper Alloy Rod |

| N/A | |

| Compound Formula | W-Cu |

| Molecular Weight | N/A |

| Appearance | Plate |

| Melting Point | N/A |

| Solubility In Water | N/A |

| Density | NA |

| Purity | N/A |

| Size | Requirement |

| Boling Point | N/A |

| Specific Heat | N/A |

| Thermo Conductivity | N/A |

| Thermal Expansion | N/A |

| Young's Module | N/A |

| Exact Mass | N/A |

| Monoisotopic | N/A |

Metal Alloy W-Cu Alloys Bar Custom Size Tungsten Copper Alloy Rod Health & Safety Information | |

| Safety Notice | N/A |

| Hazard Statements | N/A |

| Flashing Point | N/A |

| Hazard Codes | N/A |

| Risk Codes | N/A |

| Safety statements | N/A |

| RTECS # | N/A |

| Transport Information | N/A |

| WGK Germany | N/A |

Inquiry us

PREVIOUS Metal Alloy

Metal Alloy 17g/cm3 Tungsten Nickel Iron Bar Tungsten Alloy Bar

NEXT Metal Alloy