- Home

- Products

- Elementary

- Boride Powder

- 3D Printing Powder

- Sulfide Powder

- Oxide Powder

- Carbide powder

- Nitride Powder

- Silicide Powder

- Hydride Powder

- Telluride Powder

- Selenide Powder

- Stearic Acid Series

- Phosphide Powder

- Nanoparticles

- Metal Alloy

- MAX Phase

- Lithium Battery Anode

- Surfactant

- Molecular sieves

- Concrete Admixtures

- Cladding of metals

- News

- Blog

- Contact

- About

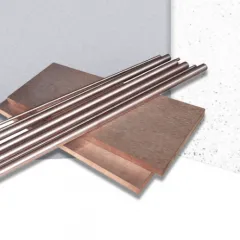

Metal Alloy W-Cu Alloys Custom Size Tungsten Copper Alloy Sheet

Tungsten-copper alloys could be deficient due to excessive processing load or impact when creating sharp corners and thin walls.

About Metal Alloy W-Cu Alloys Custom Size Tungsten Copper Alloy Sheet:

High thermal conductivity: This characteristic makes tungsten copper alloy sheets perform well in the need for rapid heat dissipation, such as radiators in electronic equipment, heat conductive sheets, etc.

High strength and hardness: Tungsten copper alloy sheet has high strength and hardness, superior to pure tungsten and pure copper. This makes it perform well when it is subjected to high loads or wear resistance is required, such as manufacturing cutting tools, wear-resistant parts, etc.

Good electrical conductivity: Although the electrical conductivity of tungsten copper alloy is lower than that of pure copper, it still has good electrical conductivity. This makes it excellent in some applications that require electrical conductivity and mechanical strength, such as manufacturing power transmission lines, cables, etc.

High-temperature resistance: Tungsten copper alloy has a high melting point and high-temperature resistance to maintain stable performance in high-temperature environment. This makes it widely used in high-temperature processing, stoves, and other fields.

Good plasticity and toughness: Tungsten copper alloy sheet has good plasticity and toughness at room temperature. This makes it excellent when customized parts, such as aerospace, medical devices, and other fields, are required.

Corrosion resistance: Tungsten copper alloy sheet has good corrosion resistance to most corrosive media, such as acid, alkali, salt, etc. This makes it widely used in the chemical industry, ocean engineering, and other fields.

Good processing performance: tungsten copper alloy sheets can be prepared by melting, casting, rolling, forging, and other processing methods. This allows it to have higher production efficiency and lower costs in the manufacturing process.

Low thermal expansion coefficient: the thermal expansion coefficient of tungsten copper alloy sheets is lower than that of pure tungsten and pure copper and has good dimensional stability. This makes it excellent in manufacturing precision parts, optical components, and other fields.

Good self-lubrication performance: In some occasions requiring self-lubrication, the performance of tungsten copper alloy is better than that of pure tungsten and copper. This makes it perform better in manufacturing wear-resistant parts such as plain bearings and bearing shells.

Biocompatibility: In some biomedical applications, tungsten copper alloy sheet has good biocompatibility and is non-toxic and harmless to biological tissues. This makes it a good application prospect in manufacturing artificial joints, vascular stents, and other medical devices.

Technica information of Tungsten Copper alloy Sheet:

| Article | 90W/ 10Cu | 85W/ 15Cu | 80W/ 20Cu | 75W/ 25Cu | 70W/ 30Cu | 60W/ 40Cu | 50W/ 50Cu |

| Density | 16.75 | 15.9 | 15.15 | 14.5 | 13.85 | 13.15 | 11.85 |

| Product | Surface | Thickness | Width | Length | |

| T | Tolerance | ||||

| Sheet of W-Cu Alloy | Grind | >=1.5-70 | +-0.05 | <=200 | <=500 |

Production Method of Metal Alloy W-Cu Alloys Custom Size Tungsten Copper Alloy Sheet:

Powder metallurgy: Powder metallurgy is a standard method for preparing tungsten copper alloy sheets. First, tungsten and copper powder are mixed according to a particular proportion, and then the alloy sheet is prepared by pressing, sintering, and rolling. The advantages of this method are that the alloy sheet with complex shape and structure can be prepared, and the properties of the alloy can be controlled by adjusting the powder ratio. However, the production cost of powder metallurgy is higher, and the surface quality of the prepared alloy sheet could be better.

Smelting method: The smelting method prepares tungsten copper alloy by melting tungsten and copper together. First, tungsten and copper are mixed proportionately and melted in a high-temperature furnace. In the smelting process, tungsten and copper form a liquid alloy, which is gradually cooled and solidified. The advantage of this method is that an alloy with high purity and high density can be prepared. However, the production cost of the smelting method is higher, and the surface quality of the prepared alloy sheet could be better.

Jet deposition method: The jet deposition method prepares tungsten-copper alloy by spraying a mixed powder of tungsten and copper into liquid copper. First, a mix of tungsten and copper is sprayed into liquid copper through a nozzle. Then, the density and properties of the alloy are controlled by controlling the temperature and pressure of the liquid copper. The advantage of this method is that the alloy with high purity and high density can be prepared, and the properties of the alloy can be controlled by adjusting the powder ratio. In addition, jet deposition can also prepare alloy sheets with complex shapes and structures. However, the production cost of jet deposition is high, and the surface quality of the prepared alloy sheet could be better.

Electrochemical method: The electrochemical process prepares tungsten copper alloy by electrolyzing a mixed solution of tungsten and copper. First, the hybrid solution of tungsten and copper is put into the electrolytic tank. Then, the tungsten and copper are deposited on the cathode by electrolysis to form an alloy. The properties of alloys can be controlled by adjusting the electrolytic parameters. In addition, electrochemical methods can also prepare alloy sheets with complex shapes and structures. However, the production cost of the electrochemical process is high, and the surface quality of the prepared alloy sheet could be better.

Mechanical alloying method: The mechanical alloying method prepares tungsten copper alloy by high-energy ball grinding of tungsten and copper powder. First, the powder of tungsten and copper is mixed according to a particular proportion, and then it is put into the ball mill for high-energy ball milling. During the ball milling, tungsten and copper powder constantly collide, deform, and eventually form an alloy. The advantages of this method are that the alloys with high purity and high density can be prepared, and the properties of the alloys can be controlled by adjusting the ball milling parameters. In addition, the mechanical alloying method can also prepare alloy sheets with complex shapes and structures. However, the production cost of the automated alloying process is higher, and the surface quality of the prepared alloy sheet could be better.

Applications of Metal Alloy W-Cu Alloys Custom Size Tungsten Copper Alloy Sheet:

Power electronics: Tungsten copper alloy sheet has good electrical and is widely used in power electronics. For example, in manufacturing power switches, rectifiers, and transformers, tungsten copper alloy sheets are used as contact materials or heat sinks. They use their high thermal conductivity to help quickly export heat and prevent overheating.

Manufacturing industry: Tungsten copper alloy sheet has good strength and hardness and can manufacture various cutting tools and wear-resistant parts. For example, in manufacturing cutting tools, tungsten copper alloy sheets are used as blade materials, whose high hardness and high wear resistance give the devices a longer service life.

Aerospace field: Tungsten copper alloy sheet's excellent performance makes it widely used in aerospace. For example, in the manufacture of aircraft and rockets, tungsten copper alloy sheets are used to manufacture parts or structural parts that work in high-temperature environments, and their good high-temperature performance and mechanical properties make the features stable in high-temperature environments.

Medical device field: Tungsten copper alloy sheet biocompatibility and low thermal expansion coefficient make it used in medical devices. For example, in the manufacture of artificial joints and vascular stents, tungsten copper alloy sheets are used as materials, whose biocompatibility and low coefficient of thermal expansion allow medical devices such as artificial joints and vascular stents to better adapt to the human environment.

High-temperature stove field: The tungsten copper alloy sheet's high melting point and good high-temperature resistance make it widely used in high-temperature stoves. For example, in the manufacture of high-temperature stoves, tungsten copper alloy sheets are used as furnace materials and heating elements, and their high melting point and high-temperature resistance make the stoves work stably in high-temperature environments.

Electronic packaging field: With the continuous development of electronic technology, tungsten copper alloy sheet is increasingly widely used. For example, in the packaging of high-density integrated circuits, tungsten copper alloy sheets are used as thermal conductivity substrate materials, and their high thermal conductivity is enough to quickly export the heat generated by the chip to prevent the impact of overheating on the chip performance.

Field of wear-resistant materials: Tungsten copper alloy sheet can be used because of its high hardness and good wear-resistant performance. For example, in the manufacture of wear-resistant parts such as mining machinery and oil drilling equipment, tungsten copper alloy sheets are used as wear-resistant layer materials or inlaying materials to improve the equipment's wear resistance and service life.

Electrical contact material field: Tungsten copper alloy sheet's electrical conductivity and hardness make it widely used in electrical contact materials. For example, in the manufacture of relays, switches, connectors, and other electrical contact elements, tungsten copper alloy sheets are used as contact materials or conductive ring materials, using their high conductivity and hardness to improve contact resistance stability.

Optical instrument field: The dimensional stability of tungsten copper alloy sheet makes it used in optical instruments. For example, in the manufacture of optical lenses, tungsten copper alloy is used as a frame material or adjusting element material, and its dimensional stability makes the frame not easy to deform, and the lens adjustment precision is high.

Nuclear industry: Tungsten copper alloy sheet has good radiation resistance, so it is used in the nuclear industry. For example, in manufacturing structural parts and shielding parts of atomic reactors, tungsten copper alloy sheets are used as materials, and their radiation resistance performance is better to protect the safety of operators and the environment.

Payment and Transportation:

Metal Alloy W-Cu Alloys Custom Size Tungsten Copper Alloy Sheet Properties | |

| Other Titles | Tungsten Copper Alloy Sheet |

| N/A | |

| Compound Formula | W-Cu |

| Molecular Weight | N/A |

| Appearance | Plate |

| Melting Point | N/A |

| Solubility In Water | N/A |

| Density | NA |

| Purity | N/A |

| Size | Requirement |

| Bold point | N/A |

| Specific Heat | N/A |

| Thermo Conductivity | N/A |

| Thermal Expansion | N/A |

| Young’s Module | N/A |

| Exact | N/A |

| Monoisotopic | N/A |

Metal Alloy W-Cu Alloys Custom Size Tungsten Copper Alloy Sheet Health & Safety Information | |

| Safety Notice | N/A |

| Hazard Statements | N/A |

| Flashing Point | N/A |

| Hazard Codes | N/A |

| Risk Codes | N/A |

| Safety statements | N/A |

| RTECS # | N/A |

| Transport Information | N/A |

| Germany | N/A |

Inquiry us

PREVIOUS Metal Alloy

Metal Alloy High Purity Molybdenum Foil

NEXT Metal Alloy