- Home

- Products

- Elementary

- Boride Powder

- 3D Printing Powder

- Sulfide Powder

- Oxide Powder

- Carbide powder

- Nitride Powder

- Silicide Powder

- Hydride Powder

- Telluride Powder

- Selenide Powder

- Stearic Acid Series

- Phosphide Powder

- Nanoparticles

- Metal Alloy

- MAX Phase

- Lithium Battery Anode

- Surfactant

- Molecular sieves

- Concrete Admixtures

- Cladding of metals

- News

- Blog

- Contact

- About

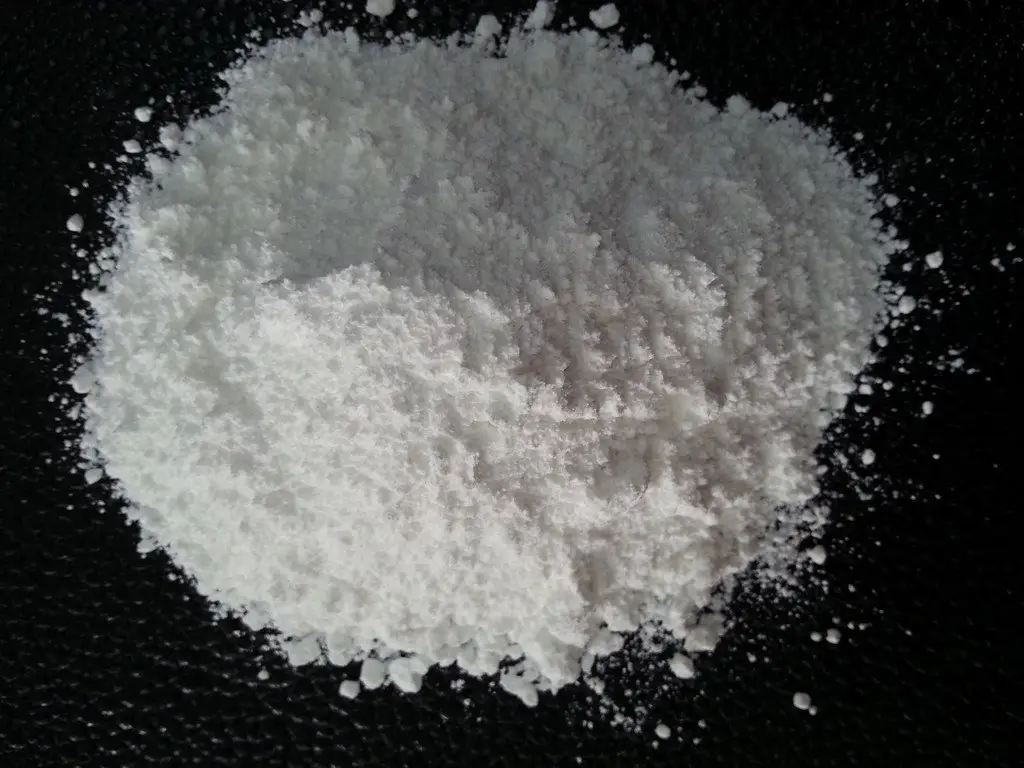

Nano Titanium Dioxide Powder TiO2 Nanoparticles

This white powder of Nano Titanium Dioxide Powder TiO2 is a loose and uniform particle. It has good dispersion effects, high specific area, and uniform particle sizes.

Description of Nano Titanium Dioxide Pulparticles TiO2 Nanoparticles:

Small particle size and large specific surface area: The particle size of nanometer titanium dioxide powder is usually below 100 nm, increasing its particular surface area and providing more reactive active sites.

High photocatalytic activity: Nano titanium dioxide powder has excellent photocatalytic activity, which can produce highly active free radicals under ultraviolet irradiation, thus degrading organic matter and killing bacteria.

Good optical properties: Nano titanium dioxide powder has high light transmittance and high reflection, which makes it widely used in optical devices, photocatalysis and other fields.

Good electrical properties: Nano titanium dioxide powder has good electrical conductivity and insulation, which makes it a potential application in electronic devices, energy storage and other fields.

Weather resistance and stability: Nano titanium dioxide powder can remain stable under high temperatures, high pressure and corrosive environments and has good weather resistance and chemical stability.

Biocompatibility: Nano-titanium dioxide powder is harmless to the human body, has good biocompatibility, and can be used in biomedical fields.

Environmental protection: The production process of nano titanium dioxide powder is relatively environmentally friendly and will not produce much waste or harmful substances, which aligns with the current green and sustainable development concept.

Application of Nano Titanium Dioxide Pulparticles TiO2 Nanoparticles:

Photocatalytic degradation of organic matter: Nano titanium dioxide powder has excellent photocatalytic activity, which can produce highly active free radicals under ultraviolet irradiation, thus degrading organic matter. Therefore, it is widely used in water treatment, air purification, self-cleaning glass and other fields.

Solar cells: Nano titanium dioxide powder has good photoelectric performance, can be used as the electrode material of solar cells, and improve the conversion efficiency of solar cells.

Coatings: nanometer titanium dioxide powder has high weather resistance, high transparency and high hiding power and is widely used in coatings, which can improve the weather ability, ultraviolet resistance and corrosion resistance of coatings.

Cosmetics: Nano titanium dioxide powder has good hiding power and dispersion and is widely used in cosmetics, which can improve cosmetics' hiding power and moisturizing effect.

Biomedical field: Nano titanium dioxide powder has good biocompatibility, is harmless to the human body, and can be used for drug carriers and biological scaffolds.

Optical devices: nanometer titanium dioxide powder has a high light transmission and high reflection and is widely used in optical devices, such as photocatalytic Windows, solar panels, etc.

Catalyst carrier: nanometer titanium dioxide powder has a high specific surface area and good chemical stability. It can be used as a catalyst carrier to improve the activity and stability of the catalyst.

Electronic devices: Nano titanium dioxide powder has good electrical properties and can be used in electronic devices, such as solar cells, photoelectric devices, etc.

Environmental protection: The production process of nano titanium dioxide powder is relatively environmentally friendly and does not produce a lot of waste or harmful substances, in line with the current concept of green and sustainable development. It can be used in environmental protection fields, such as water treatment, air purification, etc.

Production Methods of Nano Titanium Dioxide Pulparticles TiO2 Nanoparticles:

Chemical vapor deposition: It is an essential method for preparing nanomaterials. This method uses titanium compounds and oxygen as raw materials, and the chemical reaction is carried out at high temperatures to produce titanium dioxide particles. According to the different reaction conditions, nano-tio2 powders with different particle sizes and morphology can be prepared. The chemical vapor deposition method has high purity and efficiency advantages, but the equipment investment is significant, and the production cost is high.

Sol-gel method: The sol-gel method is a method of preparing nanomaterials based on liquid phase chemical reaction. In this method, titanium compounds are mixed with appropriate solvents, adding a reasonable amount of reducing agent and stabilizer, and titanium dioxide sol is obtained after heating and stirring reaction. Nano titanium dioxide powder was obtained after the sol was treated by gelation, drying and grinding. The sol-gel method can achieve industrial production, but the raw material cost is high and may produce toxic and harmful gases.

Liquid phase preparation: liquid phase practice of nano titanium dioxide powder usually includes hydrolysis, precipitation, crystallization and other steps. In this method, titanium brine solution is used as raw material, and by controlling reaction conditions (such as temperature, pH value, reaction time, etc.), the titanium brine solution is hydrolyzed to produce titanium dioxide precipitation. Nano titanium dioxide powder was obtained by filtering, washing, drying and grinding the residue.

Gas phase method: The gas phase method prepares nanomaterials by chemical reaction of gaseous raw materials in the gas phase state. This method forms titanium dioxide particles by reacting titanium-containing gas or vapor with oxygen at high temperatures. The resulting titanium dioxide particles solidify rapidly during cooling. The gas phase method can realize industrial production, but the equipment investment and production cost are significant.

Microemulsion method: It is a method of preparing nanomaterials using a microemulsion system as the reaction medium. A microemulsion system was formed by mixing titanium compounds with appropriate solvents and surfactants. In the microemulsion system, titanium compounds react with oxygen to form titanium dioxide particles. The titanium dioxide particles were dispersed and stabilized in microemulsion. After separation, washing and drying, nano titanium dioxide powder was obtained. The microemulsion method has high purity and dispersion advantages, but the raw material cost is high, and it may produce poisonous and harmful gases.

Synthetic Chemical Technology Co. Ltd. , is a trusted supplier and manufacturer of chemical material. We have more than 12 years experience providing high-quality chemicals, Nanomaterials and boride powders.

High-quality products are what you want

nano TiO2

Pulver

Please feel free and contact us to make an enquiry. (sales5@nanotrun.com

)

Nano Titanium Dioxide Powder TiO2 Nanoparticles Properties | |

| Other Titles | Nano-TiO2, Nano Titania |

| N/A | |

| Compound Formula | TiO2 |

| Molecular Weight | 79.88 |

| Appearance | white powder |

| Melting Point | N/A |

| Boiling Point | N/A |

| Density | N/A |

| Solubility of H2O | N/A |

| Exact | N/A |

Nano Titanium Dioxide Powder TiO2 NanoparticlesHealth & Safety Information | |

| N/A | |

| Hazard Statements | N/A |

| Hazard Codes | N/A |

| Risk Codes | N/A |

| Safety statements | N/A |

| Transport Information | N/A |

Inquiry us

PREVIOUS Nanoparticles

Nano Aluminium Oxide Powder Al2O3 Nanoparticles

NEXT Nanoparticles