- Home

- Products

- Elementary

- Boride Powder

- 3D Printing Powder

- Sulfide Powder

- Oxide Powder

- Carbide powder

- Nitride Powder

- Silicide Powder

- Hydride Powder

- Telluride Powder

- Selenide Powder

- Stearic Acid Series

- Phosphide Powder

- Nanoparticles

- Metal Alloy

- MAX Phase

- Lithium Battery Anode

- Surfactant

- Molecular sieves

- Concrete Admixtures

- Cladding of metals

- News

- Blog

- Contact

- About

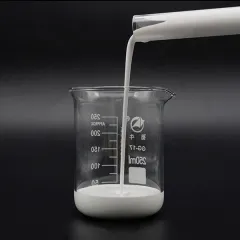

High Quality Stearic Acid Amide Emulsion

Description of Stearic Acid Amide Emulsion:

Surface activity: Stearamide is a surfactant that reduces the surface tension of liquids. Therefore, stearic acid amide emulsion has a strong surface activity, can form a single molecular layer on the water-oil interface, thereby reducing the interfacial tension, and plays a role in wetting, emulsification, dispersion, solubilization, and so on.

Emulsification: Due to its oleophilic and hydrophilic properties, stearate amide can be used as an emulsifier. In stearic acid amide emulsions, stearic acid amide molecules can mix the oil phase and water phase to form a stable emulsion. The particles in the emulsion have uniform size, narrow distribution, and high stability.

Thickening: Stearic acid amide emulsion also has a thickening effect, which can increase viscosity in the formula, thereby improving the texture and touch of the product.

Lubricity: Stearamide has a lubricating effect on the skin and can improve the smoothness and softness of the skin. In cosmetics and skin care products, stearic acid amide emulsion can be used as a lubricant to improve the use of products.

Stability: Stearic acid amide emulsion has high thermal stability and chemical stability, can remain stable at high temperatures, and is not sensitive to the effects of acid bases and oxidants.

Biocompatibility: Stearic acid amide is a biocompatible material that is widely used in cosmetics, medicine, and other fields. It can form good compatibility with biological tissues, no irritation to skin, eyes, and other tissues, and high safety.

Antistatic property: Due to the amino group and amide group contained in the molecular structure of stearic acid amide, it has an antistatic effect. Adding stearic acid amide to plastics, rubber, and other materials can reduce the friction coefficient of the surface of the product, prevent the generation of static electricity, and improve the dust resistance of the product.

Stain resistance: Stearic acid amide has stain resistance. Adding stearic acid amide to paint, paper, and other products can improve its anti-fouling performance.

Technical Information of Stearic Acid Amide Emulsion:

| Solid content | 25+-2 |

| Viscosity,cps | <=250 |

| Particle Size D50 | <=2um |

| PH | 6-9 |

How does Stearic Acid Amide Emulsion get made?

Prepare raw materials: Prepare stearic acid amide, deionized water, emulsifier, stabilizer, and other raw materials. Among them, stearic acid amide is the main component, emulsifier, and stabilizer used to form a stable emulsion.

Heating mixing: the stearic acid amide and deionized water are heated to a certain temperature and mixed evenly. Heating can improve the solubility of stearate amide, which is conducive to the subsequent emulsification process.

Emulsification: the emulsifier is added to the mixture of stearic acid amide and deionized water and continues to heat and stir so that the emulsifier is completely dissolved. The mixture is then cooled to room temperature.

Emulsion: Add stabilizer to the mixture after cooling, and stir evenly. The stabilizer can enhance the stability of the emulsion and prevent the emulsion from delamination and breaking milk.

Adjust the pH: Control the properties of the emulsion by adjusting the pH. The pH is usually adjusted to between 7-8 for optimal emulsion stability.

Filtration and packaging: The resulting emulsion is filtered out of impurities and packaged. Packaging can be selected in appropriate containers or bags to protect the emulsion from contamination and oxidation.

Applications for Stearic Acid Amide Emulsion:

Cosmetics: Stearic acid amide emulsion has a wide range of applications in cosmetics. Due to its lubricity, stability, and thickening properties, it can be used as a raw material for cosmetics such as moisturizers, sunscreen, and facial masks. In addition, stearic acid amide emulsion can also be used to prepare soap, shampoo, body wash, and other personal care products.

Medical field: stearic acid amide emulsion has certain antibacterial properties and biocompatibility, so it is also widely used in the field of medicine. It can be used as a drug carrier for the preparation of drug delivery systems. It can also be used as pharmaceutical excipients for the preparation of medical devices and drugs.

In the field of plastics and rubber, stearic acid amide emulsion can be used as a plasticizer and rubber processing aid, which can improve the processing and mechanical properties of plastics and rubber. Adding stearic acid amide emulsion to plastic and rubber products can improve their flexibility, wear resistance, and anti-aging properties.

Textile field: stearic acid amide emulsion can be used as a softening agent and antistatic agent for textiles, which can improve the softness, antistatic properties, and comfort of textiles. Adding stearic acid amide emulsion in textile processing can improve the feel, gloss, and wrinkle resistance of the fabric.

Coating field: Stearic acid amide emulsion can be used as a coating additive, which can improve the leveling property, scratch resistance, and weather resistance of the coating. The surface properties and protective properties of coatings can be improved by adding stearic acid amide emulsion.

Other fields: In addition to the above areas, stearic acid amide emulsion can also be used in electronics, automotive, agriculture, and other fields. For example, it can be used as a lubricant and cleaning agent for electronic components, as an anti-wear agent and protective agent for auto parts, and as a carrier and additive for agricultural pesticides and fertilizers.

Shipping and Packing of Stearic Acid Amide Emulsion:

You can choose from many kinds of packaging depending on your stearic Acid amide Emulsion Quantity.

Packaging of Stearic Acid amide Emulsion:

25kg/barrel

Emulsion shipment of Stearic Acidamideamide

Could be sent by sea or air as soon as possible after receipt of payment.

Stearic Acid Amide Emulsion, Stearic Acid supplier, Stearic Acid storage

Inquiry us

PREVIOUS Stearic Acid Series

High Quality EBS Ethylene Bis Stearamide Emulsion

NEXT Stearic Acid Series