- Home

- Products

- Elementary

- Boride Powder

- 3D Printing Powder

- Sulfide Powder

- Oxide Powder

- Carbide powder

- Nitride Powder

- Silicide Powder

- Hydride Powder

- Telluride Powder

- Selenide Powder

- Stearic Acid Series

- Phosphide Powder

- Nanoparticles

- Metal Alloy

- MAX Phase

- Lithium Battery Anode

- Surfactant

- Molecular sieves

- Concrete Admixtures

- Cladding of metals

- News

- Blog

- Contact

- About

SLES Sodium Lauryl Ether Sulphate CAS 68585-34-2, 68%-72%

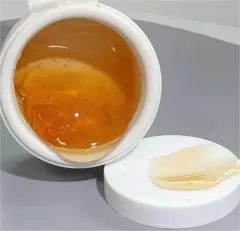

The sodium Lauryl Ether Sulphate exhibits excellent decontamination properties, emulsification and foaming abilities, as well as resistance to hardwater.Solid Content: 68%-72%

Description of SLES, Sodium Lauryl Sulfate:

Physical properties: Sodium lauryl ether sulfate is a white or light yellow powder, soluble in water, with a slight pungent odor. Its molecular structure contains lauryl ethyl ether and sulfate ions, and the relative molecular weight is large, so it has high stability.

Chemical properties: Sodium lauryl ether sulfate is an anionic surfactant and, therefore, has the basic chemical properties of anions, such as precipitating reactions with cationic surfactants and forming insoluble salts with metal ions. In addition, sodium lauryl ethyl ether sulfate can undergo hydrolysis reactions under acidic or alkaline conditions to produce corresponding alcohols and sulfates.

Surface activity: Sodium lauryl ether sulfate has excellent surface activity, can form micelles in an aqueous solution, and reduces the surface tension of water, thereby improving the wetting and dispersion of oil or dust. Therefore, adding sodium lauryl ether sulfate to detergents, shampoos, body washes and other products can enhance its decontamination effect.

Irritant: Sodium lauryl ether sulfate has a certain irritant, so paying attention to personal protective measures during use is necessary to avoid direct contact with the skin or inhalation of large amounts of dust. In addition, when using detergents, shampoos, and other products containing sodium lauryl ether sulfate, care should be taken not to overuse them to reduce skin irritation.

Biodegradability: Sodium lauryl ether sulfate in the natural environment can be degraded by microorganisms into harmless substances such as water and carbon dioxide. Therefore, its residual amount in the environment is low, and its environmental impact is small. However, if you accidentally enter the water or soil in the process of use, it may also cause certain harm to aquatic organisms or plants.

Technical Parameter SLES Sodium Laryl Ether Sulfate

| Product Code | Shortname | Purity | PH | Odor | Appearance |

|---|---|---|---|---|---|

| Sulfate de sodium Lauryl Ether | SLES | 68%-72% | 6.5-11 | A slight characteristic smell | White to light Yellow Translucent Gel |

Applications of SLES is Sodium Lauryl Ether Sulphate:

Detergent industry: Sodium lauryl ether sulfate is the most widely used detergent in the industry. It is used to prepare various detergents, such as washing powder, washing liquid, dishwashing liquid, etc. Sodium lauryl ether sulfate has excellent washing properties and can effectively remove stains and oil stains on clothing and utensils.

Personal care products: Sodium lauryl ether sulfate is also widely used to prepare personal care products, such as shampoo, body wash, hand sanitizer, etc. It can enhance the foam richness and fineness of personal care products so that users can feel comfortable and refreshed when enjoying bathing or personal hygiene.

Cosmetics industry: Sodium lauryl ether sulfate is also widely used in the cosmetics industry, such as facial cleansers, toners, creams, etc. It can be used as an additive, such as a wetting agent and emulsifier in cosmetics, to improve the moisture and elasticity of products and make the skin more delicate.

Petroleum industry: In the petroleum industry, sodium lauryl ether sulfate and other chemical reagents are used as emulsifiers to exploit oil wells and transport oil products. It can effectively reduce the interfacial tension of oil and water, promote oil and water separation, and improve oil recovery efficiency.

Textile industry: In the textile industry, sodium lauryl ether sulfate can be used as a softener, antistatic agent and other additives in the processing and treatment of textiles. It can enhance the softness and antistatic properties of textiles and improve their quality and added value.

Production Method of SLES is Sodium Lauryl Ether Sulphate:

Direct esterification: Direct esterification is one of the main methods for preparing sodium lauryl ether sulfate. The method is to esterify lauryl alcohol with sulfuric acid to produce lauryl sulfate and then to react with ethylene oxide to produce lauryl ethyl ether sulfate.

Transesterification: The transesterification process is also a method for preparing sodium lauryl ether sulfate. The method is to conduct a transesterification reaction between lauryl alcohol and fatty acid to produce a corresponding ester and then esterify with sulfuric acid to produce lauryl sulfate. Then, lauryl sulfate and ethylene oxide were added to produce lauryl ether sulfate. The transesterification method requires a catalyst and higher reaction temperature but can obtain higher product quality and yield than the direct esterification method.

Alkylation: Alkylation is another method for preparing sodium lauryl ether sulfate. The method is adding an alkylating agent to ethylene oxide under alkaline conditions to produce the corresponding ether, then esterifying it with sulfuric acid to produce lauryl ethyl ether sulfate. The alkylation process requires catalysts and a higher reaction temperature but can obtain higher product quality and yield.

Other methods: Besides the above three methods, several others can prepare sodium lauryl ether sulfate. For example, lauryl alcohol can be reacted with chlorosulfonic acid to produce the corresponding sulfonate, which is then hydrolyzed with sodium hydroxide to produce sodium lauryl ether sulfate. In addition, lauryl ethyl ether sulfate can be prepared by oxidizing lauryl alcohol and other methods.

Packing & Shipping SLES Sodium Lauryl Ether Sulphate

SLES Sodium Lauryl Sulphate is available in a variety of different packaging.

SLES Sulphate of Sodium Lauryl Ether Sulfate:

1kg/bottle or 25kg/barrel.

SLES (Sodium Lauryl Ether Sulphate) shipping

The shipment can be made by air, sea or express as soon after payment as possible.

Sodium Lauryl Ether Sulphate Property | |

| Alternative Names | N/A |

| CAS Number | 68585-34-2 |

| Compound Formula | RO(CH2CH2O)nSO3Na |

| Molecular Mass | N/A |

| Appearance | White to light Yellow Translucent Gel |

| Melting Point | N/A |

| Boiling Point | N/A |

| Density | N/A |

| Solubility In H2O | N/A |

| Exact Quantity | N/A |

Sodium Lauryl Sulfate Health & Safety Information | |

| Sign Word | N/A |

| Hazard Statements | N/A |

| Hazard Codes | N/A |

| Risk Codes | N/A |

| Safety Declarations | N/A |

| Transport Information | N/A |

Inquiry us

PREVIOUS Surfactant

Sorbitan monopalmitate CAS 26266-57-9

NEXT Surfactant